From outside the industry, a timber merchant may look like a fairly niche operation. All of the equipment, the beam saws, the precision cutting tools, they are surely only used by architects and carpenters? This is not the case. Our equipment can be used by a variety of people, from artists, inventors, joiners and decorators. If your project requires precision cutting with a 0.1mm degree of accuracy then we can help you.

What We Can Offer

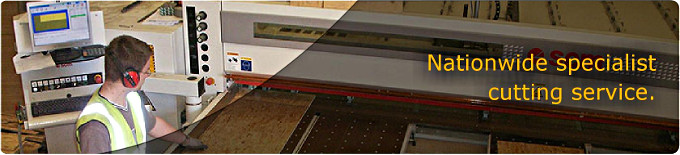

We are an independent company with extensive experience and have invested in state-of-the-art technology. By pairing powerful beam saws with computer precision, practically any shape or design can be crafted.

Automated Machinery

Computer numerically controlled cutting and routing are two of our most useful and versatile practices. They rely on the automation of engineering tools and cutting equipment. By feeding them specific pieces of information, for example certain points and paths they must follow, saws and blades can quickly set to work yet still produce a high level of accuracy. The speed of the operation helps to keep down costs, delivering a quality result at a reasonable price.

With some of the biggest beam saws in the UK we can work with sheets up to 6 metres long and 3.8 metres wide. Materials we can work with include MDF, plywood and plastic.

Cut To Size MDF

Medium density fibreboard (MDF) is a versatile resource often used by engineers to make cheap prototypes of inventions. This allows them to test the models and work out any flaws before more substantial materials are used.

MDF also appeals to artists as it is the most warp resistant wood panel available, ensuring that pictures of any medium will endure for years to come.

MDF is an engineered wood made by breaking down elements of hardwood and softwood into fibres, then mixing it with wax and resin to bind it together. MDF sheets and panels are made by applying high temperatures and pressure. A denser composition than plywood, it is a ubiquitous building material. This is also due to the fact that by its very nature it contains no knots or similar impurities that could make crafting and construction difficult. Unlike hardboard, the internal structure of MDF allows it to withstand heat and moisture without distorting.

As a merchant we are completely aware of the responsible sourcing of materials. We have achieved Chain of Custody certification, which means that customers can use our services without worrying that they are contributing to the destruction of forestry.

Our staff have the necessary expertise and experience required when it comes to cutting MDF and using automated machinery. They can make the most of the computer equipment, which can work with sheets up to 90mm thick, and can answer queries regarding specific projects. Designs can be sent through to them beforehand, whether they are detailed blueprints or simple drawings, and they can provide advice that will make the most of the cutting process.