If you’re in the business of supplying wooden furniture, raised beds, shelters and so on for gardens, you might be set to experience a rise in demand for your products over coming weeks. After all, summer is just around the corner and so many consumers will be thinking about investing in new items to ensure their outdoor areas are up-to-scratch.

Of course, if you’re going to be able to meet demand for your products, it’s important you find the ideal timber merchant to supply your materials. By achieving this, you can help ensure your production runs smoothly and your finished items look the part.

The rise of the ‘outdoor room’

In the past, gardens were predominantly seen as areas for plants, grass, ponds and so on. However, there’s an increasing trend toward a more functional use of these spaces and individuals are now inclined to invest in decking, tables, chairs, recliners and other products to help them enjoy their gardens.

Commenting on this issue in the Financial Times recently, Victoria Maw said: “Although Victorian walled gardens might have featured the odd stone bench, their only function was to provide a place to sit and admire the plants. If tea was taken outdoors, it was usually on a table that was carried outside and then swiftly taken away.

“But attitudes have changed over the past 50 years. Nowadays people expect their garden to fulfil a range of different functions and furniture has evolved to meet this need.”

Boosting living space

Ms Maw went on to suggest that more and more furniture is being designed to meet the brief of an “outdoor living room” and a rising number of people are investing considerable sums in outdoor shelters, some of which can cost tens of thousands of pounds.

How we can help

When you’re on the lookout for wood to help you meet demand among your customers, you might benefit from taking a look at what we have to offer here at Booker Timber. We’re experts when it comes to producing superb timber panels.

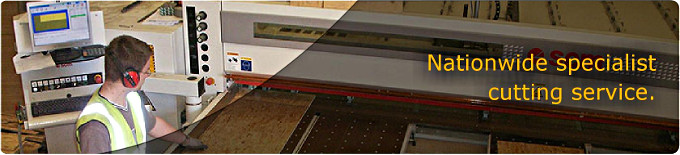

Our CNC beam saws are among the largest in the UK and we have the capacity to handle and cut sheets of up to six metres in length and four metres in width, with board thicknesses of up to 90 millimetres.

A broad selection and great value

Whether you’re after MDF, chipboard, plywood, orientated strand board, hardboard or melamine faced chipboard, we’re the firm to come to.

Also, our cut to size chipboard and plywood sheets represent superb value for money and to save you even more cash, our optimisation software will calculate the most efficient way to cut your boards where different sizes are required. As well as lowering your costs, this reduces waste, which is good news for the environment.

Find out more

If you’re keen to find out more about what we have to offer, you can take a look around the rest of our website. Meanwhile, there’s also the option of getting in touch with our friendly and professional team by phone.