So you’ve found your timber supplier, and got your list of what you need. Now it’s time to choose your wood. Take your time – and don’t forget your tape measure!

Use it to make sure the ends of the planks are the right size. Also check these for splits, and the direction of the growth rings. Check both sides for knots, and any twisting. Remember that bad knots could end up in your cut-offs.

Also check to see whether the wood is straight by looking down its length from one end. It should not be twisted or bowed. And look for any changes in grain that could have an effect on the finished job.

If you are pulling wood out from a pile, keep checking as you pull out. Don’t pull the timber out any further than you have to if you are not happy with it.

Obviously, if you are transporting the wood yourself, you will have to come prepared with rope, straps and a rag to put on the end of a long load so you can drive home in safety.

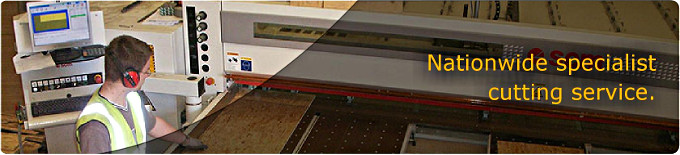

At Booker Timber, we have a wide range of high quality timber products, and state of the art CNC machinery together with powerful software so we can provide fast, accurate and efficient solutions to your panel requirements, wherever you are in the UK.

We can help whether you need mdf cutting or want to buy cut to size mdf, cut to size plywood or other types of wood. There’s more online.